The precision casting industry is evolving with advancements in technology and materials:

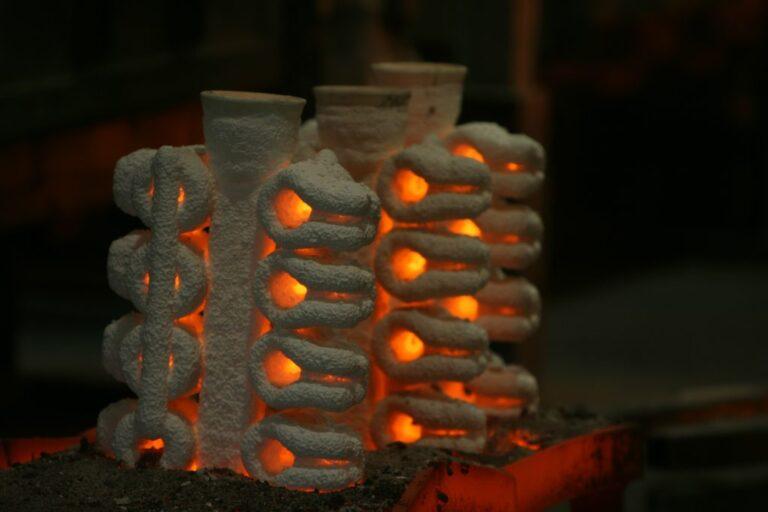

Additive Manufacturing: 3D printing of wax patterns and ceramic molds reduces lead times and enables rapid prototyping.

Digital Simulation: Software tools optimize mold design and predict defects before production.

Eco-Friendly Practices: Recyclable ceramic slurries and energy-efficient furnaces reduce environmental impact.

Advanced Alloys: Development of high-entropy alloys (HEAs) and nanostructured materials for enhanced performance.

Automation: Robotic systems streamline pattern assembly, shell coating, and finishing processes.

Future Directions:

Integration of AI for real-time process monitoring and quality control.

Expansion into new industries like renewable energy (e.g., wind turbine components).

Continued focus on sustainability through closed-loop material recycling.

These innovations ensure that precision casting remains at the forefront of advanced manufacturing, meeting the demands of modern industries.

These articles provide a comprehensive overview of precision casting, covering its principles, processes, materials, advantages, and future trends. Each section is concise yet detailed, making it accessible for readers seeking in-depth knowledge.