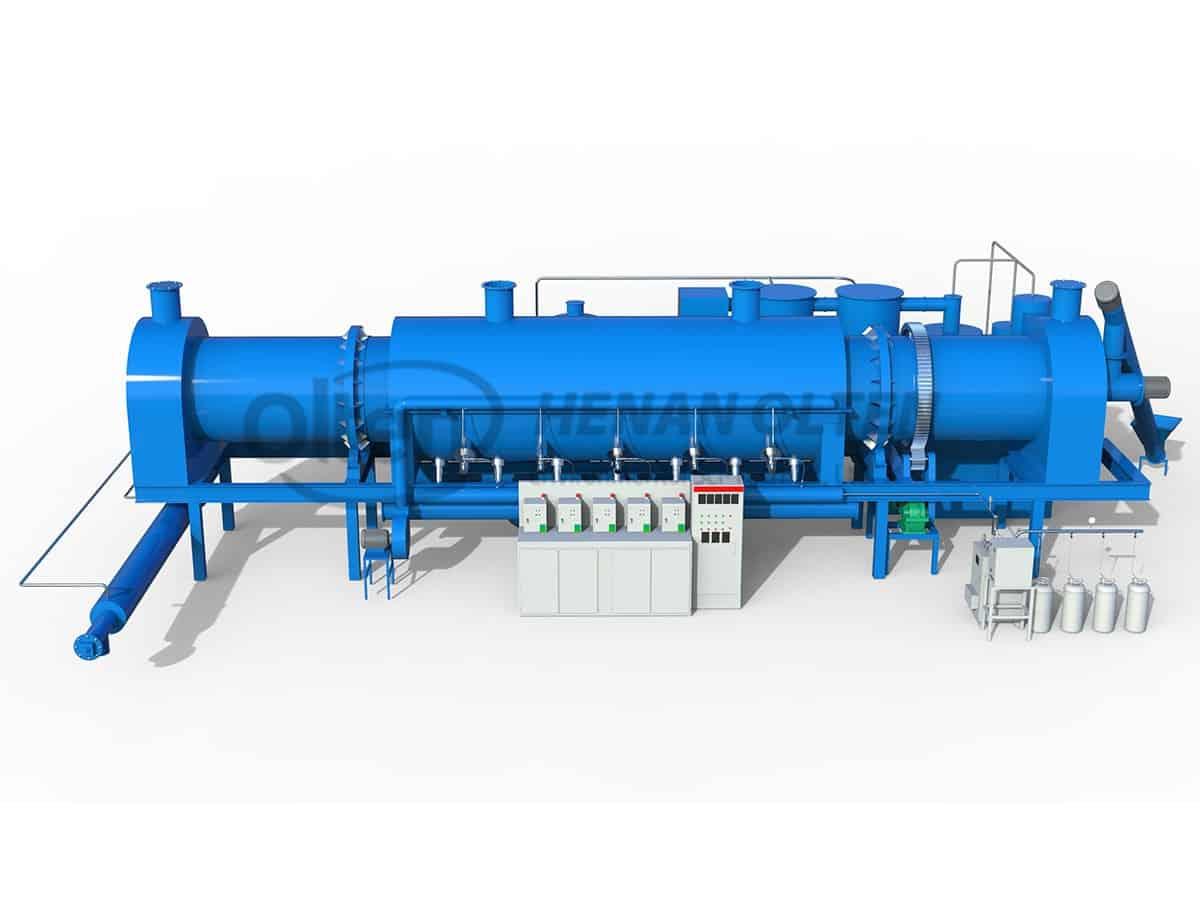

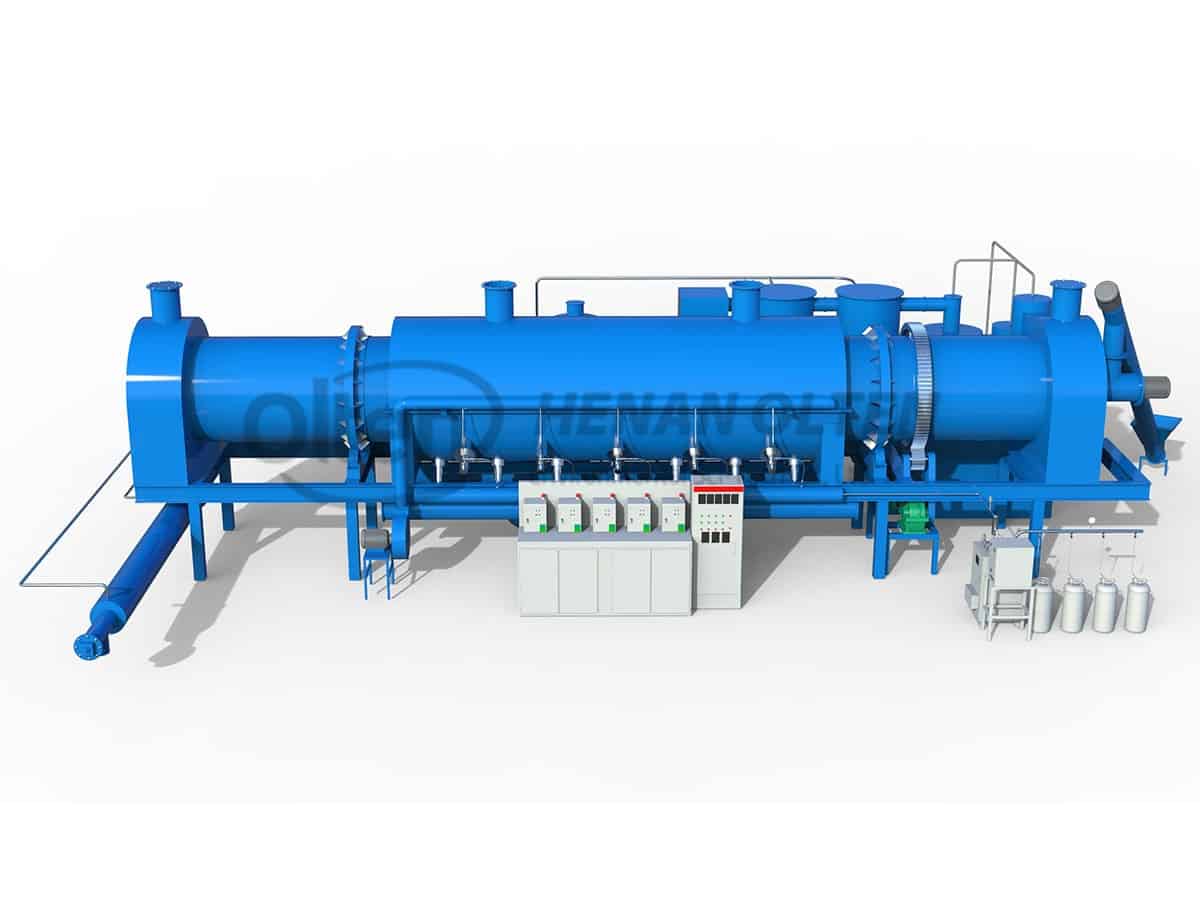

Forest waste disposal and resource recycling machines, such as wood charcoal making machines, have been recognized as a cost-effective method of disposing of wood waste while also achieving resource recycling objectives in a number of countries around the world. It has been exported to a number of countries around the world since it was first introduced to the market, and it is currently in use in a number of those countries as well.

Unlike other machines, the machines to convert wood into charcoal are a single machine that can perform a variety of tasks. Various waste types, including biomass such as palm shells, sawdust, and rice hull and municipal solid waste such as municipal solid waste and sewage sludge, can be processed by them.

The process of making wood carbonization furnace from wood with a Charcoal Machine is straightforward.

The carbonization process can be completed in the following ways with the assistance of a Wood Charcoal Making Machine:

For the manufacturing process to be as efficient as possible, Wood carbonization furnace is necessary to pre-treat the raw materials before they are used in the process. A crusher and dryer are required in order to remove any remaining moisture from the wood and to cut the wood into more manageable pieces for transportation. Because of this, the heating of your materials will be more uniform, resulting in greater efficiency in your operation.

Following that, high-temperature pyrolysis, sulfur release, flue-gas emissions, and charcoal enrichment are all a part of the overall process. A top-heating technology known as 1 fire with 2 steps has been implemented as a result of the manufacturing processes, with the ultimate goal of cost reduction and energy conservation in mind.

For any questions about the procedure, you can also contact Beston Henan Machinery of China, and we will respond as soon as possible, if necessary.

Gas is being used to pass through wood in order to achieve this goal. Manufacturing Equipment for Charcoal Production

Combustible gas is a necessary by-product of the carbonization of wood, and it can be produced in large quantities. A large amount of it is produced and it is used in a variety of industrial applications, including the generation of electrical power. According to the general consensus, a wood-wood carbonization furnace furnace will most likely be preheated for approximately half an hour with conventional fuels such as natural gas, wood, or charcoal before being used. Combustible gas begins to be produced in small quantities as soon as the specified temperature is reached. The use of gas in the first and second steps of a process is one of the most important factors in the achievement of technological breakthroughs, and it is used in the first and second steps of the process. In the vast majority of cases, spray-dedusting systems are used to purify the gas, with the sulfur in the mixture being removed from the mixture during the purification process in the vast majority of cases. Furthermore, because the gas has a high burning value, it can be recycled to the dryer tool and the warmth furnace after this step is completed, avoiding the need to re-use natural gas, wood, or coal as a fuel for the furnace after this step is completed is completed.

The equipment for drying wood charcoal that is attached to the wood charcoal manufacturing machine is referred to as the drying equipment.

High-temperature carbonization furnace of wood chips is accomplished by burning the wood chips, which results in the production of artificial charcoal, wood vinegar, and tar. It is anticipated that this product, which will be the most significant product produced, will be used in a large number of applications. A wide range of applications exist for wood charcoal, including use in industrial settings to manufacture steel-covering agents and use in agriculture to produce fertilizer or improve the quality of the soil, depending on the application. Wood charcoal can be used in a variety of settings, including industrial and agricultural settings. Charcoal BBQs are intended for use in the home, and the charcoal used in them is specifically designed for this purpose. They are still widely used as specific chemicals in the manufacture of a variety of products such as oil paint, mosquito repellant, and a variety of other things despite the fact that their functions in the wood are not nearly as important as their functions in the vinegar and tar in the woodThere is a very good chance that the manufacturer will generate significant economic profits from the sale of all of the finished goods.

After being subjected to additional processing, wood chip can be formed into a variety of shapes, including granules, balls, and strip-type . When determining this, the needs of the customer in terms of the equipment required for production are taken into consideration. The price of shaped charcoal is higher than that of unshaped , in part because it is more visually appealing. This results in higher profits for the retailer.