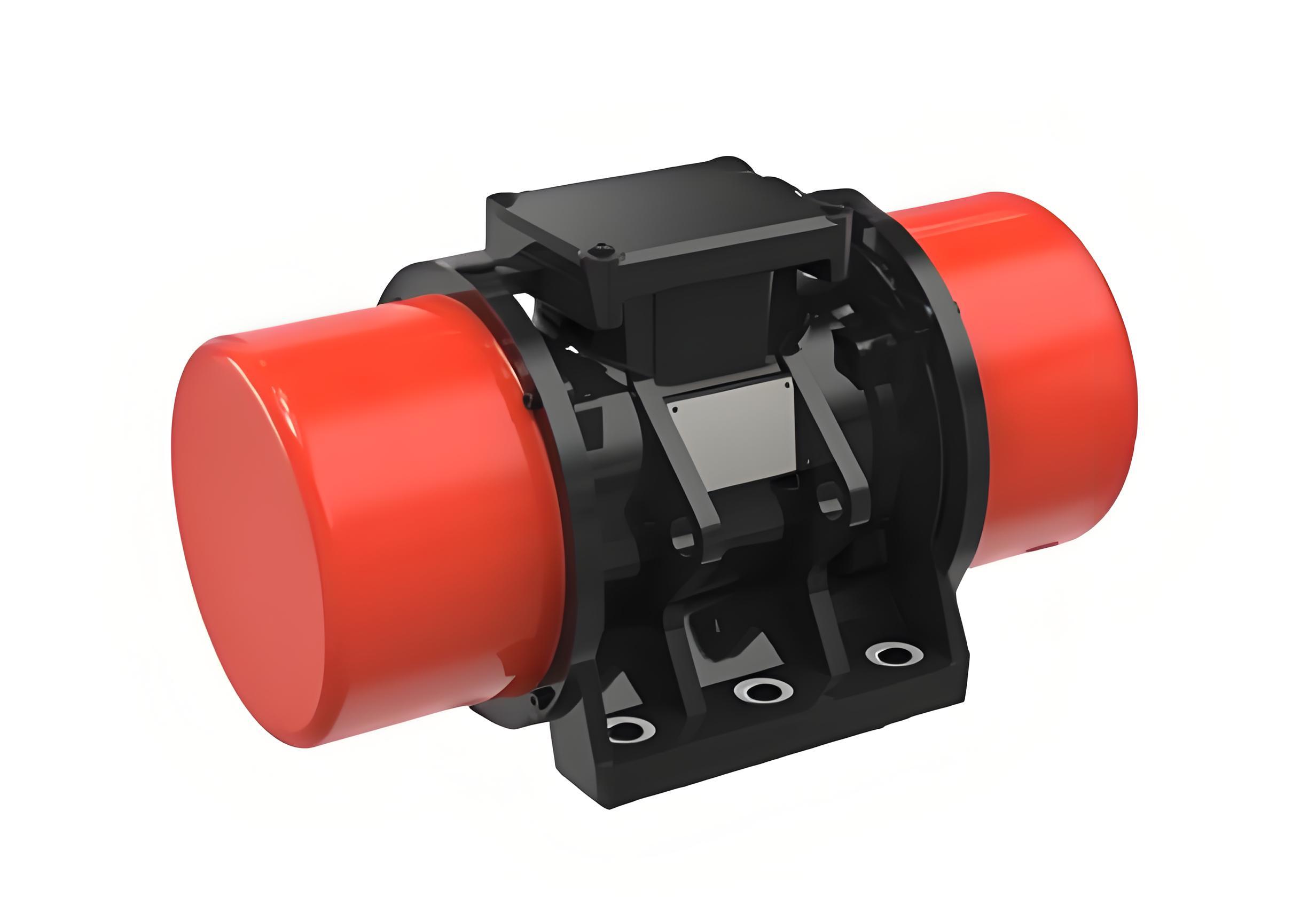

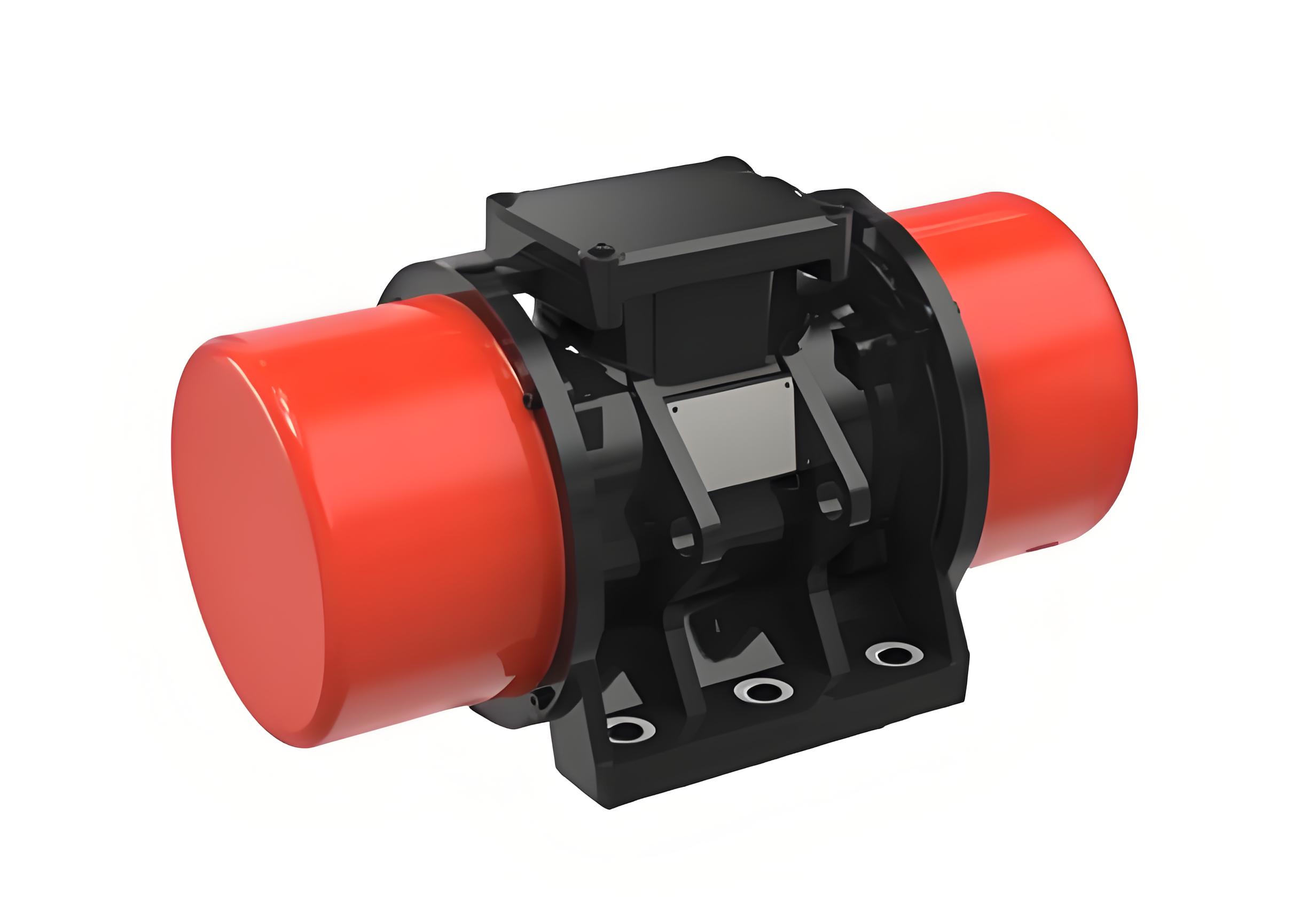

In modern industrial production, efficiency, reliability, and cost-effectiveness are key drivers of success. Vibration motors play an essential role in ensuring smooth material handling, uniform processing, and optimized production workflows. Among these, the LZDA/LZDB Side Plate Vibration Motor has emerged as a popular solution across industries such as chemical engineering, metallurgy, construction, food processing, and mining. By combining robust design with precise vibration control, this motor contributes significantly to operational efficiency and product quality.

What is the LZDA/LZDB Side Plate Vibration Motor

The LZDA/LZDB Side Plate Vibration Motor is a specialized mechanical device that generates linear or circular vibrations, depending on installation and design configuration. Unlike traditional motors, its side-mounted eccentric plates allow for adjustable vibration force and amplitude, providing precise control over material flow in various applications.

Key characteristics include:

-

Side Plate Design: Ensures uniform vibration transmission, reduces wear on motor components, and allows flexible installation.

-

Durable Construction: High-quality steel and alloy components make it resistant to corrosion, abrasion, and continuous operation.

-

Adjustable Vibration Force: By modifying the eccentric weights, operators can control vibration intensity to match the processing needs.

-

Compatibility: Works seamlessly with hoppers, feeders, screens, silos, and other industrial machinery.

The motor is commonly used to improve material flow in bulk handling, prevent clogging, and enhance processing efficiency in production lines.

Advantages of Using the LZDA/LZDB Side Plate Vibration Motor

1. Improved Production Efficiency

One of the primary benefits of the LZDA/LZDB Side Plate Vibration Motor is its ability to maintain a continuous and uniform flow of materials. In industries such as mining or chemical processing, inconsistent material flow can cause production delays and equipment wear. By providing steady vibration, the motor ensures that materials move smoothly, reducing downtime and maximizing throughput.

2. Precision Control Over Vibration Intensity

The side plate design allows operators to adjust the eccentric weight to fine-tune vibration force. This adaptability means the motor can handle a wide range of materials—from fine powders to heavy aggregates—without causing damage or excessive wear. Precise control also allows integration into sensitive production processes where uniform distribution is critical.

3. Robust and Durable Performance

Industrial environments demand equipment that can withstand harsh conditions. The LZDA/LZDB motor is built with high-strength steel and alloy components to resist corrosion, abrasion, and mechanical stress. Its sealed structure prevents dust and moisture intrusion, which extends service life and reduces maintenance requirements.

4. Cost-Effective Operations

Investing in reliable vibration motors can significantly reduce operating costs. The LZDA/LZDB motor minimizes material waste caused by clogging, ensures consistent production rates, and decreases downtime due to maintenance. Over time, this results in measurable savings for industrial facilities, both in operational and labor costs.

5. Versatile Industrial Applications

Thanks to its adaptable design, the LZDA/LZDB Side Plate Vibration Motor is widely used in multiple industries:

-

Mining: Facilitates the smooth flow of ores, coal, and aggregates in feeders and hoppers.

-

Food Processing: Ensures uniform distribution of powders, grains, and granules on processing lines.

-

Construction: Enhances concrete, sand, and gravel movement in mixers and screening machines.

-

Chemical Engineering: Maintains steady flow of powders, granules, or raw materials in production.

-

Metallurgy: Prevents material blockages in furnaces, silos, and feeders.

This versatility makes it an essential tool for any industrial operation requiring efficient material handling.

Installation and Maintenance Tips

Proper installation and regular maintenance are crucial to maximizing the performance of the LZDA/LZDB Side Plate Vibration Motor. Here are key recommendations:

Correct Mounting: Ensure the motor is securely mounted to the equipment frame to avoid vibration loss or structural damage.

Alignment: Check the alignment of eccentric weights to prevent imbalance, which can reduce efficiency and increase wear.

Lubrication: Follow manufacturer guidelines for periodic lubrication of bearings to maintain smooth operation.

Inspection: Regularly inspect motor housing, side plates, and mounting bolts for wear, cracks, or looseness.

Adjustments: Fine-tune eccentric weights periodically to match changing operational needs and material types.

By following these steps, facilities can extend the lifespan of the motor and maintain consistent production efficiency.

Conclusion

The LZDA/LZDB Side Plate Vibration Motor is a versatile and reliable solution for optimizing industrial processes. Its side plate design, adjustable vibration intensity, durable construction, and wide range of applications make it an indispensable tool in material handling, screening, and processing operations.

By adopting these motors, industrial facilities can achieve:

Higher production efficiency

Reduced material waste

Lower maintenance and operational costs

Enhanced automation capabilities

Longer equipment lifespan

Whether in mining, construction, food processing, chemical production, or metallurgy, the LZDA/LZDB Side Plate Vibration Motor ensures smooth operations, improved workflow, and cost-effective performance.

https://www.sudazhendong.com/optimizing-the-production-process-advantages.html