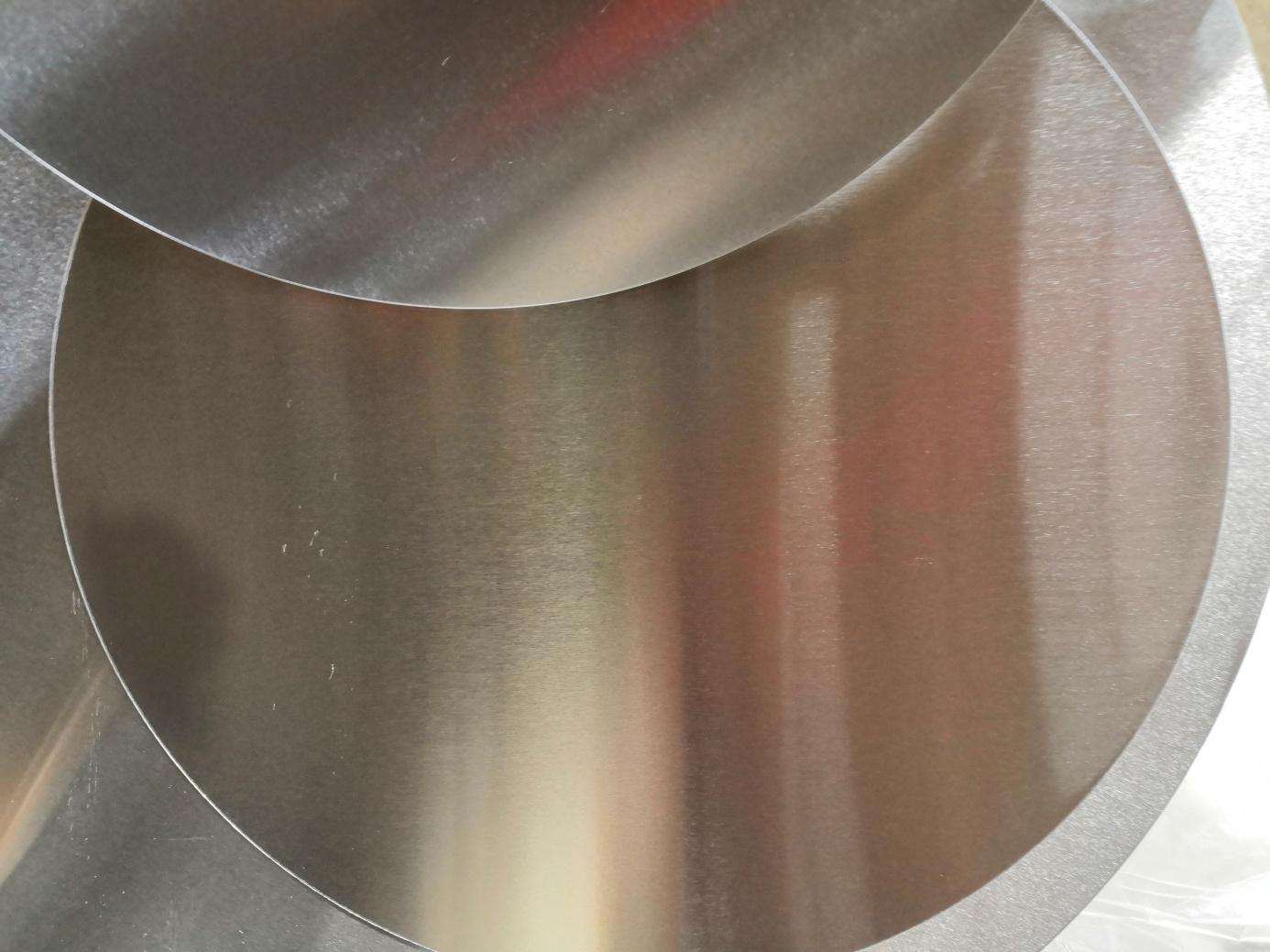

1050 aluminum circle for spinning is used as a material for lamp covers, domestic utensils, oil tanks, automobile parts and buildings. Though circles of many tempers can be further processed by spinning, the most suitable is O, which is the softest. Characteristics of 1050 aluminum circle sheet perfect meet requirements for spinning. Aluminum is featured by good tensile strength and low hardness, embodying both plasticity and fluidity required for spinning. It will undergo work hardening and grain refinement during the cold spinning process, and the natural strength of the blank will be much better than other processes under the same wall thickness after spinning. The rise in resilience reduces the accuracy of the material after molding. The lower the hardness of the material, the better the surface quality after spinning. In comparison to other circle metals, aluminum circle discs boast the lowest hardness, the strongest tensile strength, the biggest elongation and the highest inner pressure, proving to be the best spinning material of all.We have cold rolled and hot rolled 1050 aluminum circle for spinning, with tempers of O, H12, H14, H16, H18, H22, H24, H26, H32, H34 and H36. Thickness can be as small as 0.4mm and as large as 10mm. The diameter can be customized. In addition to 1050, aluminum circle discs of other alloys, such as 1060, 1070, 1100, 3003, 5052, 5251, 6061, 6063 and so on, are suitable for spinning, too, but the harder the material, the more difficult it is to have it processed.Why do people choose Huawei in purchasing spinning aluminum circles? Because we have 20 years manufacturing history and 12 years export experience, serving thousands of clients from all over the world.

1050 1060 1070 1100 3003 5052 5251 aluminum circle for spinni

Read More

MMOEXP Warborne Above Ashes:Warborne: Above Ashes – Understanding the Role of the Drifter Mole in Game Progression

In Warborne: Above Ashes, one of the more intriguing and essential tools for progression is the...

Some changes you need to know in WOW TBC Classic Patch 9.1.5

In response to the influx of feedback since the WOW beta was released. The developers are...

Case Studies: Organizations That Gained a Competitive Edge Through ISO 27001 Certification

In today’s digital era, data security is a defining factor in business success....

How to Choose the Best Tyre Shop in Singapore for Your Car Tyres and Tyre Replacement Needs

Choosing the right tyres and a reputable tyre shop in Singapore is essential for vehicle safety,...