5052 aluminum sheet plate is a high-performance aluminum–magnesium alloy belonging to the 5xxx series. Magnesium is the primary alloying element, typically present at approximately 2.2–2.8%, providing the alloy with excellent strength, corrosion resistance, and weldability. Among non-heat-treatable aluminum alloys, 5052 is recognized for its superior fatigue strength and overall mechanical performance.

One of the most notable characteristics of 5052 aluminum sheet plate is its outstanding resistance to corrosion, particularly in marine and coastal environments. The magnesium content enhances resistance to saltwater, humidity, and industrial pollutants, making this alloy suitable for long-term exposure in harsh conditions. As a result, 5052 aluminum is widely used in applications where durability and environmental resistance are critical.

In terms of mechanical properties, 5052 aluminum sheet plate offers higher strength than 3xxx series alloys while maintaining good ductility. It is commonly supplied in tempers such as O, H32, and H34, allowing manufacturers to balance strength and formability according to application requirements. The alloy exhibits good elongation and excellent fatigue resistance, making it suitable for components subjected to repeated stress.

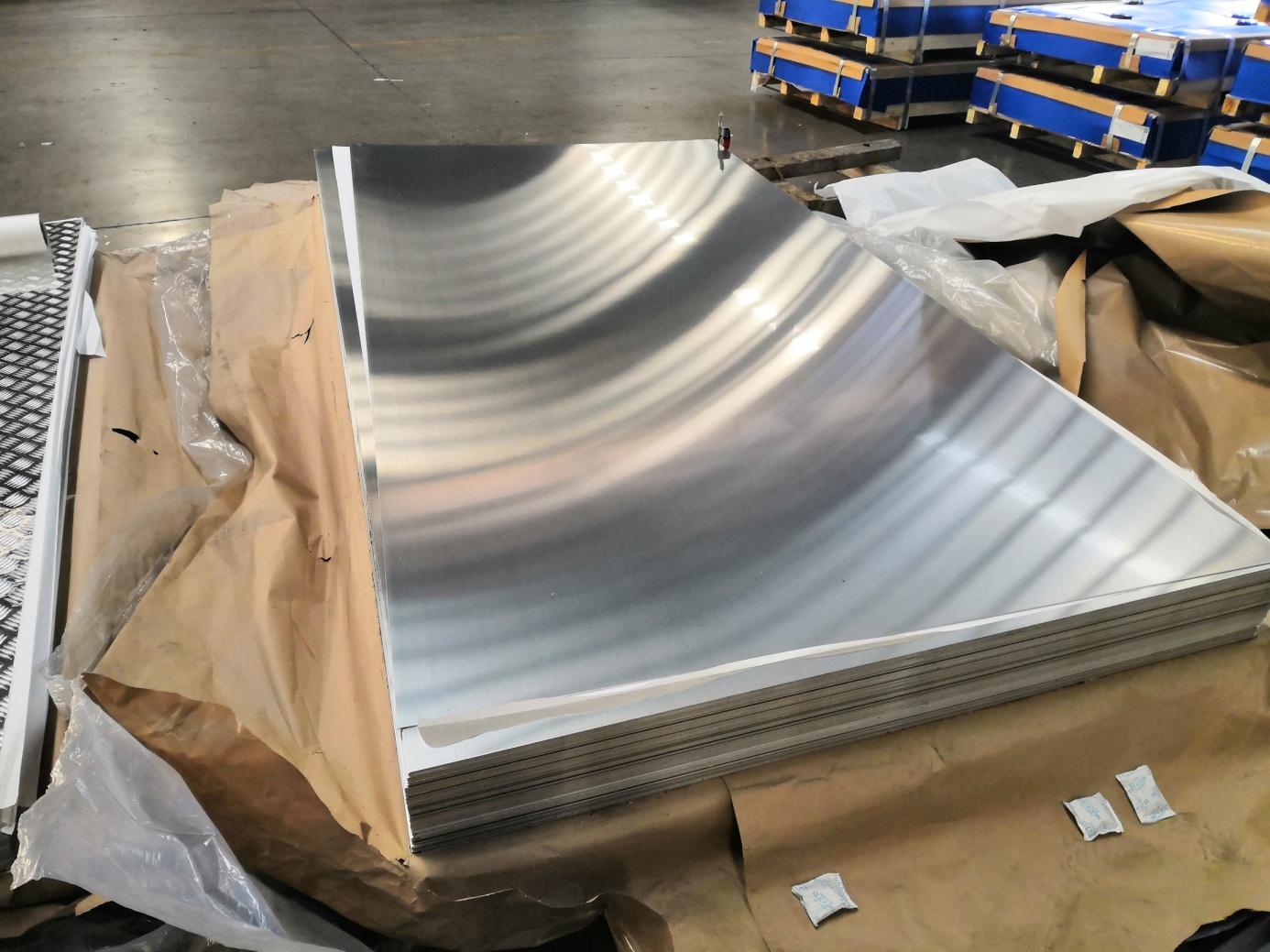

Additionally, 5052 aluminum sheet plate demonstrates excellent weldability and formability. It can be easily formed, bent, and shaped without cracking, and it performs well in common welding processes, including TIG and MIG welding. Its smooth surface finish also makes it suitable for anodizing and coating, enhancing both aesthetic appearance and functional protection.