You want to save money and make your facility work better. The industrial closed-loop cooling tower from Shenzhen Haoyi Refrigeration Technology Co., Ltd. helps you do this. You spend less money because you use less water. You also need less maintenance. It uses energy better, too. Many industries now use this system. It can cut down freshwater use by up to 70%.

See how these groups get help:

| Industry Sector | Applications |

|---|---|

| Industrial Sector |

Key Takeaways

-

Closed-loop cooling towers use up to 70% less water. This means you can save a lot on water bills.

-

These systems need less maintenance because they are sealed. The sealed design stops contamination and scaling. This saves you time and money on repairs.

-

Closed-loop cooling towers use advanced heat exchange technology. This makes them more energy efficient. You can save money on electricity bills.

-

If you switch to a closed-loop system, your operating costs can go down. It also protects your investment by stopping expensive repairs.

-

Picking a closed-loop cooling tower helps the environment. It uses resources better and lowers harm to nature.

Water Savings with Industrial Closed-loop Cooling Tower

How Closed Loop Design Reduces Water Use

You want to spend less on water and help the planet. The industrial closed-loop cooling tower lets you do both things. This system uses a closed circuit cooling tower design. It keeps water inside pipes all the time. The water does not touch the outside air. This stops most of the water from turning into vapor. You lose very little water this way. You do not need to add much new water, so you save money each month.

-

Dry cooling takes heat from hot water and moves it to cool air. The water does not leak out.

-

The closed circuit cooling tower keeps water from turning into vapor because it is sealed.

-

You use less water, so your water bill goes down.

The cooling tower closed loop system works in many places. You can use it in small factories or big power plants. The size can be from 10T up to 1000T. You get steady work and water-saving features. The design is small, so it fits your space.

Cost Impact for Industrial Facilities

You save real money when you use closed circuit cooling systems. These towers use the same water again and again. You do not have to buy as much new water. New technology in closed circuit cooling tower units helps stop water from turning into vapor. Studies show you can use up to 50% less water than old systems.

Here are some main product features and what they do:

| Feature | Benefit |

|---|---|

| Closed Circuit Design | Stops water from turning into vapor and floating away |

| Minimal Spray Water Replenishment | Only a little new water is needed |

| Overall Efficiency | Cuts water loss much more than old systems |

You also help nature. Closed loop cooling towers use water again and keep it clean. You use less water from your town or city. You do not have to pay as much to clean dirty water. This system helps you use resources better and keeps your business working well.

Tip: When you use a closed circuit cooling tower, you save money and help make your industry greener.

Maintenance Reduction in Closed Circuit Cooling Tower

Preventing Contamination and Scaling

You want your cooling system to stay clean and work well. The closed circuit cooling tower helps with this. It keeps water inside pipes, so dirt cannot get in. This design stops most contamination and scaling. You do not have to worry about algae or minerals building up.

Here is a simple table that shows how the closed circuit cooling tower compares to open systems:

| Advantage | Closed Circuit Design | Open System Design |

|---|---|---|

| Contamination Prevention | Sealed system prevents contaminants | Exposed to external elements |

| Efficiency | Reduced scaling and fouling | Higher risk of scaling |

| Equipment Longevity | Cleaner water circulation reduces wear | More wear and tear |

-

The closed circuit cooling tower keeps water clean by keeping it away from the outside.

-

You see less scaling and fouling, so heat moves better.

-

Cleaner water helps your equipment last longer.

Lower Repair and Upkeep Costs

You save money because you do not need to clean or fix your system as much. The industrial closed-loop cooling tower uses self-cleaning parts and smart monitoring. These features watch your system all the time. If something changes, you get an alert right away. You can fix small problems before they get worse.

-

Auto-correction features change settings to keep things working.

-

Real-time monitoring helps control scaling and corrosion.

You spend less time and money on repairs. The closed circuit cooling systems keep water clean, so you do not need to stop for cleaning. This means your business keeps working without long breaks.

Closed loop cooling towers often use strong materials like 316L stainless steel. With good care, these towers can last over 20 years. Certifications like CE and ISO show your cooling tower is safe and reliable. You can feel sure your system will last and work well.

Tip: When you pick a closed circuit cooling tower, you make maintenance easier and costs lower.

Energy Efficiency of Closed Loop Cooling Towers

Advanced Heat Exchange Technology

You want your building to use less energy and save money. The closed circuit cooling tower uses special heat exchange technology to help you. This technology moves heat from water to air in a better way. You get cooler water and use less energy.

Here is a table that shows how these features help you:

| Technology | Benefit |

|---|---|

| High-Efficiency Fill Retrofits | Moves heat faster, so you need less fan power or can cool more water. |

| Variable Frequency Drives | Adjusts fan and pump speeds to match demand, saving electricity. |

| Water Conservation Retrofits | Uses less fresh water by recycling or collecting rainwater. |

| Data Analytics | Finds ways to improve efficiency that you might not see right away. |

You can save a lot of energy with these features. Many people say they save over half their energy by changing how fans work in induced draft cooling towers. Hybrid cooling towers can save almost one-third more energy than older towers.

Long-term Cost Savings

You want your cooling system to work well all the time. Closed circuit cooling tower systems keep working even when it is hot outside. They stop dirt and minerals from building up, so your equipment stays safe. This means you do not have sudden breakdowns or expensive repairs.

-

Closed loop cooling towers help data centers and factories stay cool and reliable.

-

The design keeps water clean, so you do not lose time fixing problems.

-

You spend less on water, chemicals, and electricity.

Facilities that switch to a cooling tower closed loop system often see lower operating costs. You protect your investment and avoid costly repairs. Good water treatment keeps your system working well for many years. You also help the planet by using less energy and water.

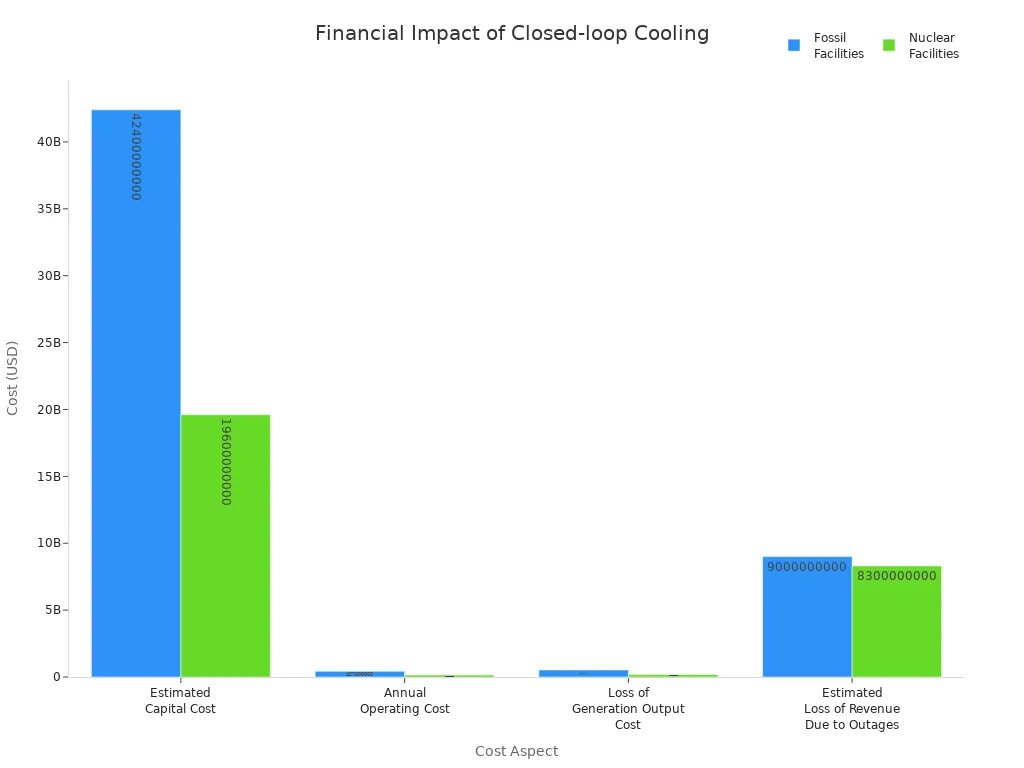

Here is a chart that shows the financial impact for large facilities:

You can see that switching to an industrial closed-loop cooling tower can lead to big savings over time. You get a system that works well, saves money, and helps your business for many years.

You get many good things when you pick closed circuit cooling towers for your factory. You spend less money because you use less water. You do not need to fix or clean the system as much. The system uses energy in a better way. These good points help many different jobs and places. The table below shows how closed loop cooling towers help your business:

| Top Features to Look For in a Closed Circuit Cooling Tower Manufacturer | Benefit |

|---|---|

| Water Conservation | Lower costs, sustainability |

| Enhanced Water Quality | Fewer repairs, longer life |

| System Versatility | Fits many industries |

You make a smart choice that helps your business save money for a long time.

FAQ

How does a closed-loop cooling tower save water?

You use less water because the system recycles it. The closed pipes stop most water from escaping. You do not need to add much new water. This helps you save money and protect the environment.

What industries can use this cooling tower?

You can use this cooling tower in many places. It works well for factories, power plants, data centers, and chemical plants. The design fits both small and large operations.

How does smart monitoring help you?

Smart monitoring checks your system all the time. You get alerts if something changes. You can fix small problems before they become big. This keeps your system running smoothly.

Is the system hard to maintain?

You do not need to spend much time on maintenance. The closed design keeps water clean. Self-cleaning parts and strong materials make the system last longer. You save time and money.

https://www.szdxzl.cn/industrial-closed-loop-cooling-tower-saves-money-reasons.html