When most people think of a transformer box, they imagine a simple metal or composite enclosure. In reality, an electrical transformer box is a highly engineered system: it must protect high-voltage and low-voltage components, ensure safety, provide thermal and environmental shielding, and potentially integrate monitoring and control systems. At Tianrui, we approach transformer box design not as a commodity, but as a turnkey engineering asset — combining mechanical, electrical, software, and visual/monitoring integration to deliver optimal performance, reliability, and safety.

1. Technical Foundations: Electrical Transformer Box — Key Concepts & Specifications

1.1 Classification and Rating Context

An electrical transformer box must be tailored to the load requirements: capacity (measured in kVA), voltage class, phase arrangement (single-phase, three-phase), and intended usage (residential, commercial, industrial).

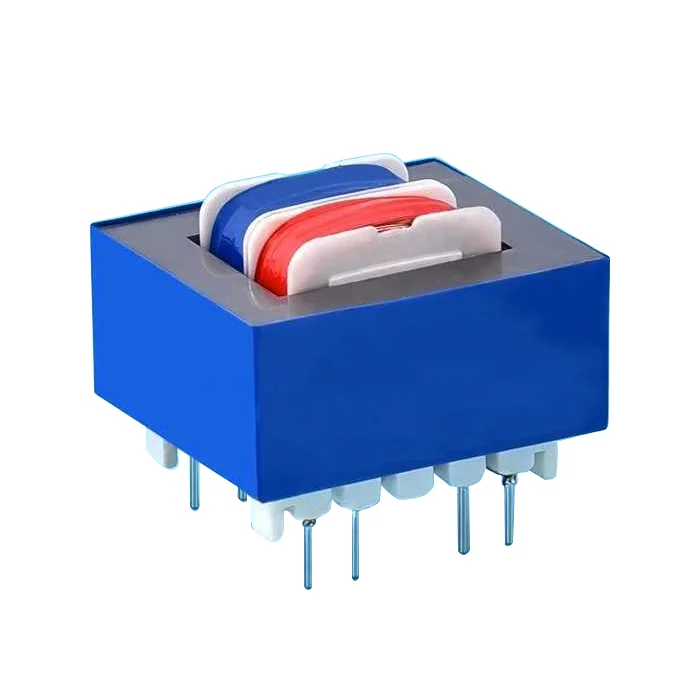

Box-type or pad-mounted transformer enclosures are common because they integrate the transformer core, high-voltage switchgear, and low-voltage distribution components into a single modular, sealed unit — offering space-efficient, secure and maintenance-friendly solutions.

1.2 Structural & Safety Design Principles

-

Compartmentalization: Independent compartments for high voltage (HV), transformer tank (or dry-type core), and low voltage (LV) ensure safety and service segregation.

-

Enclosure Materials & Protection Ratings: Materials such as galvanized steel or stainless steel, with anti-corrosion coatings and flame-retardant partitions, are used to achieve rugged durability and environmental resistance.

-

Access Control & Interlocks: Mechanical interlocks ensure that doors cannot open unless circuits are de-energized, protecting maintenance staff from accidental contact.

-

Thermal & Ventilation Management: Proper airflow design — using natural or forced ventilation, heat dissipation grilles, or cooling systems — manages temperature rise inside the enclosure, preserving insulation health and performance.

-

Noise & Environmental Adaptability: For units with high loads, sound-dampening measures and environmental hardening (against moisture, particulates, seismic load, etc.) are considered in design.

2. Tianrui’s Differentiated Integration Strategy for Transformer Boxes

At Tianrui, we leverage cross-disciplinary integration to optimize transformer box design:

2.1 Custom Engineering & Modularity

We design transformer box systems based on specific customer requirements, modularizing HV switchgear, transformer compartment, and LV distribution sections — enabling scalable deployment and easier transport/installation. This modular design aligns with industry practices for prefabricated-type solutions.

2.2 Advanced Safety & Monitoring Integration

Beyond standard safety interlocks, Tianrui incorporates digital monitoring (temperature, humidity, partial discharge sensors, SCADA integration) to provide predictive maintenance and real-time alerts. These smart features are embedded within the enclosure design.

2.3 Materials & Compliance Excellence

Our enclosures use high-grade metal (galvanized or stainless), anti-corrosion coatings, and compartmental fire-retardant partitions to meet rigorous electrical and mechanical standards. We also design with accessibility for grounding, cable termination, and secure lugs for safe installation and maintenance.

2.4 Customization for Environmental Needs

We tailor designs according to environmental stressors: humidity, salt spray, temperature extremes, or industrial exposure. Options include acoustic dampening, climate control, and modular sealing to maintain performance in any setting.

3. Application Use-Cases & Benefits Galore

3.1 Residential & Urban Deployments

In urban settings, box-type transformers inside secure enclosures serve multiple households while maintaining public safety because connections are fully enclosed.

Tianrui’s designs ensure minimal footprint, tamper-proof access, and visual appeal alongside robust safety.

3.2 Industrial / Commercial Installations

For manufacturing plants, data centers or large facilities requiring high power, Tianrui’s transformer boxes provide reliable load management, safety control, and integration with facility monitoring, reducing downtime and operational risk.

3.3 Renewable Energy & Special Projects

Our modular enclosures are suited for renewable energy sites (solar, wind) and challenging environments, offering corrosion resistance, smart monitoring, and flexible scalability for future expansion.

4. Design Best Practices & Technical Considerations

4.1 Safety Clearance & Installation Norms

Correct clearance around enclosure ensures safe operation; for some transformer types, maintenance access and ventilation requirements are strictly enforced (e.g. front clearance, bottom airflow).

All electrical interconnections must follow rigorous testing (polarity, insulation, thermal rise) and grounding procedures to ensure safety and compliance.

4.2 Thermal Management & Maintenance Facilitation

Tianrui emphasizes temperature sensors and ventilation strategies in enclosure design to anticipate thermal stress and prolong insulation life.

Removable panels, labelled wiring schemes, and modular layout facilitate easier inspection, replacement, and future upgrades.

4.3 Human-Machine Interface & Monitoring

Modern transformer boxes benefit from integrating control panels with remote monitoring, alarm systems, and condition tracking — a core offering in Tianrui’s product portfolio, enabling predictive maintenance and operational analytics.

4.4 Durability & Compliance Assurance

We adhere to international standards for transformer enclosure manufacturing: robust materials, rigorous finishing, and safety ratings to ensure long-term reliability even in harsh environments.

5. Why Choose Tianrui for Your Transformer Box Solutions

-

End-to-end Integration: From design, manufacturing, to monitoring systems — Tianrui delivers turnkey solutions optimized for each project.

-

Tailored Customization: Whether small residential units or heavy-duty industrial setups, we adapt capacity, protection, and functionality to your needs.

-

Safety-first Engineering: Built-in interlocks, compartment separation, environmental hardening and smart controls ensure safety and compliance.

-

Future-ready Technology: We incorporate IoT-ready interfaces and monitoring systems that align with Industry 4.0 standards for efficient asset management.

Conclusion

An electrical transformer box is more than just a metal box: it’s a strategic engineering system that demands meticulous attention to electrical design, safety, thermal control, and integration. At Tianrui, we bring together expertise across disciplines to offer transformer enclosures that are safe, reliable, and intelligent. Whether for urban, industrial, or specialized applications, our solution framework ensures performance, security, and future scalability.

https://www.hbtrec.com/systems-level-guide-to-electrical-transformer-boxes.html