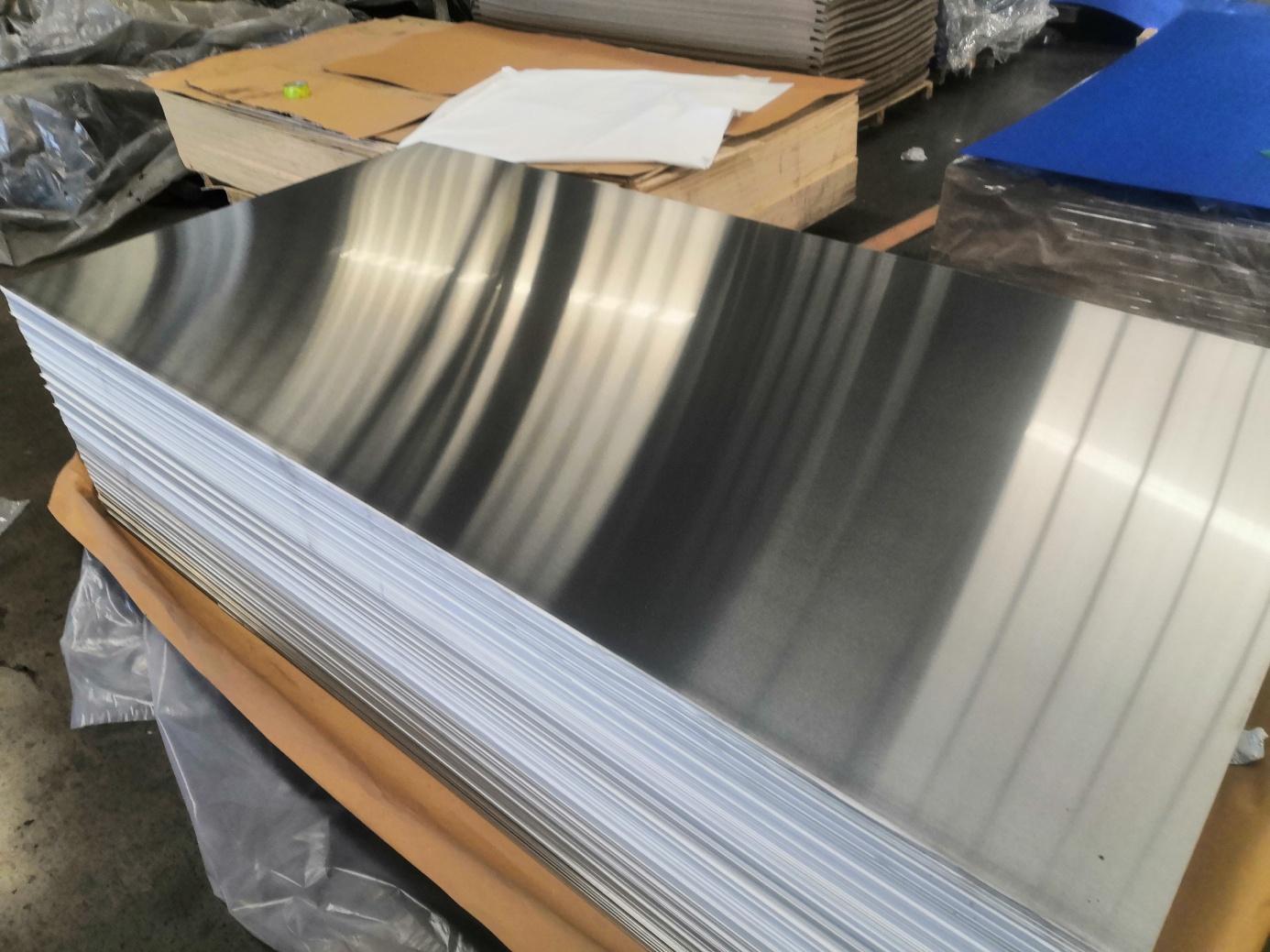

1050 aluminum sheet alloy is formed with the aid of including a small amount of copper detail to pure aluminum, it has amazing forming characteristics, excessive corrosion resistance, precise weldability and electric conductivity. 1050 aluminium sheet is widely used in merchandise with low necessities on energy, such as chemical gadget, sheet metallic processing parts, deep drawing or spinning concave vessels, welding parts, warmth exchangers, clock surfaces and plates, nameplates, kitchen utensils, decorations, reflectors, and many others. The chemical and mechanical properties of aluminum sheet 1050 are as follows.

The chemical composition of 1050 aluminum sheet plate:Aluminum( Al): ninety nine.Five%,Silicon (Si) ≤ zero.25%,Copper (Cu) ≤ 0.05%,Magnesium (Mg) ≤ zero.05%,Zinc (Zn)≤0.05%,Manganese (Mn)≤zero.05%,Titanium (Ti) ≤ zero.03%,Vanadium( V) ≤ zero.05%,Iron (Fe): 0.000-zero.Four hundred

The mechanical houses of 1050 aluminium sheet:Tensile electricity σb (MPa): ninety five~125Conditional yield electricity σ0.2 (MPa) ≥seventy five

The warmth remedy system of 1050 aluminum sheet plate:1) completely annealed: heated 390-430 °C; , the protecting time 30 ~ 120min with the cloth of different thickness; 30 ~ 50 °C / h speed with the furnace to three hundred °C, then air cooling.2) rapid annealing: Heating 350 ~ 370 °C; the preserving time of 30 ~ 120min with the cloth of various thickness, empty or water-cooled.Three) Quenching and aging: quenching 500-510°C, air cooling; artificial getting old ninety five-105°C for 3h, air cooling; natural growing older 120h with room temperature.

1050 aluminum sheet in one thousand series aluminum alloys

Read More

Buy NBA 2K23 MT Safe

The moment that NBA 2K23 enters its fifth season, the most enthusiastic team has to 2K23 MT...

RELX เรื่องเล่าควันยุคใหม่ จากตำนานสู่ไลฟ์สไตล์

relx: จุดเริ่มต้นของนิยามควันยุคใหม่

...

SP2S新浪潮:一次性小煙的極致進化論

當便利成為現代人最奢侈的享受,思博瑞以SP2S一次性電子煙系列掀起一次性小煙革命。這款掌心大小的霧化設備,內建預充式煙油與電池,開盒即吸、無需充電,用完即棄的特性,徹底解放忙碌族群的雙手。而當你...

[ NEW VIRAL!]] Zara Dar Original Video Trending Short Clip mma

CLICK THIS L!NKK