In today’s competitive manufacturing landscape, accurate product labeling is no longer just a regulatory requirement—it’s an essential part of brand consistency, traceability, and production efficiency. A packaging labelling machine plays a central role in automating this critical process, ensuring that every product leaving the production line is clearly identified, compliant, and ready for distribution.

The Evolving Role of Labeling in Modern Packaging

Labeling is one of the last but most important steps in packaging. It provides consumers, distributors, and regulators with essential information about a product — from batch numbers and expiry dates to safety warnings and traceability codes.

For enterprises, errors in labeling can lead to compliance risks, product recalls, and loss of consumer trust. This is why many manufacturers are upgrading from manual or semi-automatic systems to intelligent, automated packaging labelling machines that deliver speed, precision, and consistency.

How a Packaging Labelling Machine Works

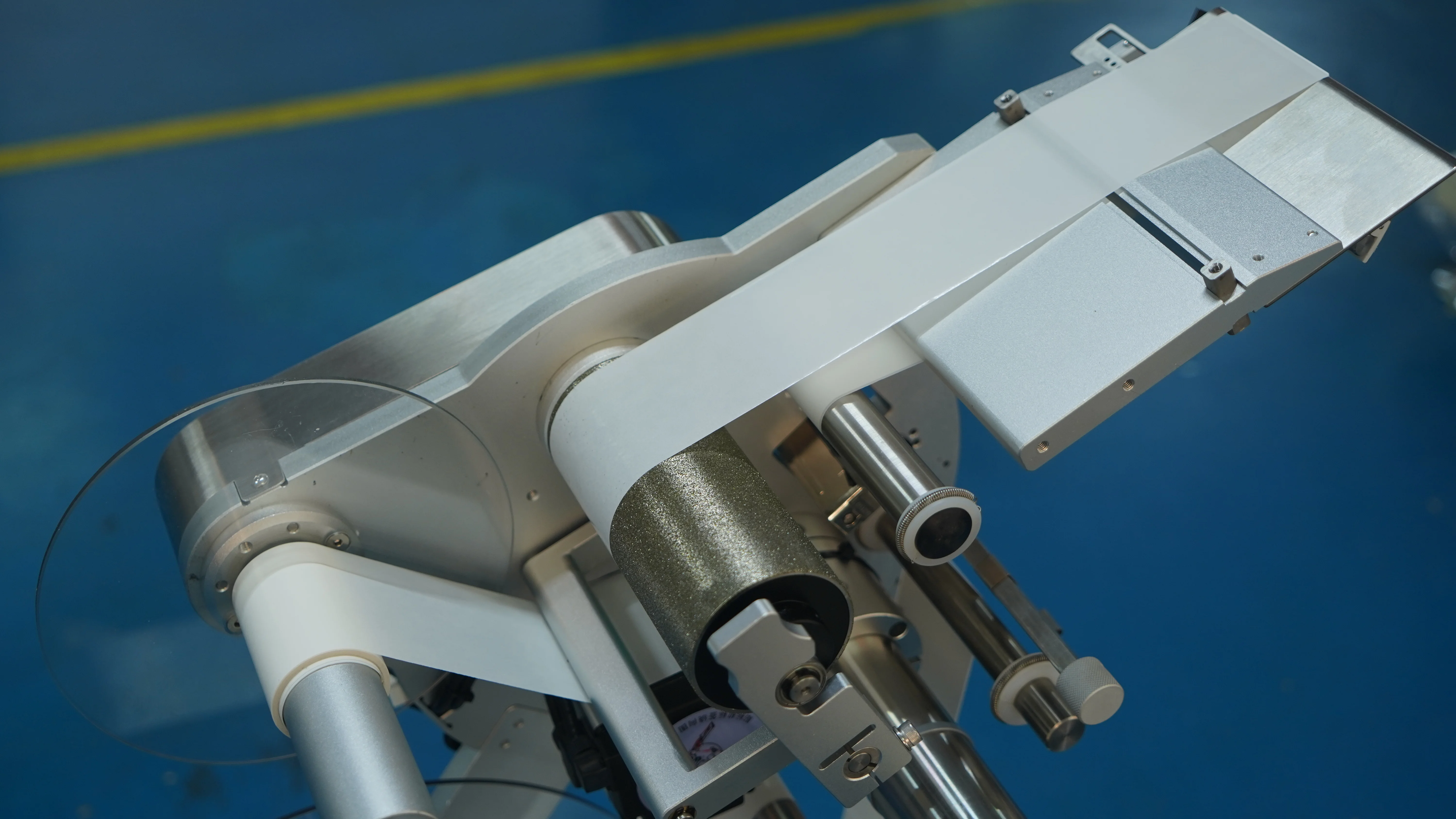

Modern labeling systems are designed to integrate seamlessly into existing production lines. Depending on the packaging type — bottles, cartons, pouches, or boxes — labeling machines can apply wrap-around, top, side, or dual-sided labels with millimeter-level accuracy.

A typical system consists of the following key modules:

-

Feeding & Alignment System: Ensures that products are evenly spaced and correctly oriented before labeling, avoiding skewed or misplaced labels.

-

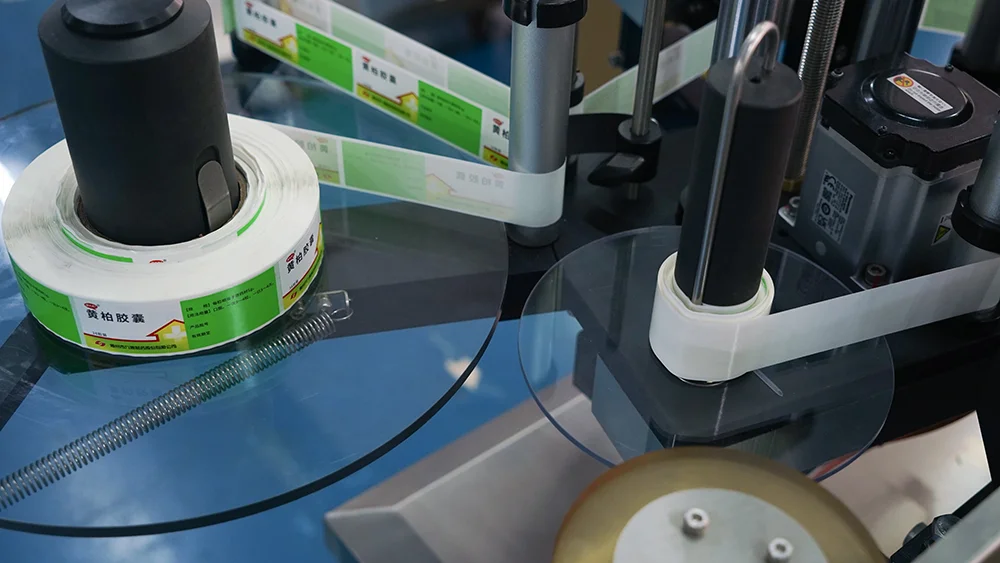

Label Dispensing Mechanism: Uses servo-driven motors to control label feeding tension, ensuring smooth application even at high speeds.

-

Detection and Verification Unit: Optical sensors or vision cameras confirm label placement, code accuracy, and presence.

-

Rejection and Sorting Mechanism: Automatically removes non-compliant products to maintain overall line quality.

Some advanced packaging labelling machines also include integration with vision inspection or print-and-apply coding systems, allowing real-time batch coding or barcode printing directly on the label.

Key Benefits for Enterprises

1. Improved Labeling Precision

Servo-controlled label applicators and vision verification systems minimize deviations, ensuring a clean, professional finish on every product.

2. Enhanced Efficiency and Throughput

Automatic labeling significantly reduces bottlenecks at the end of the line, maintaining consistent output even during high-volume production.

3. Compliance and Traceability

By linking label data with ERP or MES systems, enterprises can achieve end-to-end traceability and meet global labeling regulations in industries like pharmaceuticals, food, and chemicals.

4. Flexibility Across Packaging Formats

Modern labeling systems can quickly switch between bottle sizes, shapes, and packaging materials, enabling manufacturers to handle multiple SKUs without extended downtime.

5. Reduced Operational Costs

Automation reduces reliance on manual labor and minimizes waste from mislabeling or rework, leading to long-term cost efficiency.

Trends Shaping the Future of Labeling Automation

As Industry 4.0 continues to influence production systems, labeling technology is also evolving. Future-ready packaging labelling machines are being equipped with IoT connectivity, data logging, and predictive maintenance features. These allow operators to monitor performance metrics, detect label roll depletion, and schedule maintenance proactively — reducing unplanned downtime.

Conclusion

For enterprises striving to maintain product quality and operational excellence, adopting an intelligent packaging labelling machine is a practical step toward full-line automation. It ensures accuracy, consistency, and compliance while offering flexibility to meet future production demands.

Whether in pharmaceuticals, cosmetics, or FMCG manufacturing, labeling automation is no longer just a cost-saving tool — it’s a cornerstone of modern packaging strategy and a foundation for building consumer trust and brand reliability.

Learn more about automatic labeling solutions that can be tailored to your production needs.