The 5083 aluminum alloy sheet has many blessings including mild weight, medium strength, and clean forming. It could be used inside the manufacture of vehicle elements, ships and truck tank. But, 5083 aluminium sheet plate has a incredibly excessive Mg content. It is easy to precipitate β segment (Mg2Al3) on the grain boundary when positioned at room temperature for a long time. The precipitation of β section will make the material age soften.

So that it will reduce the unfavorable outcomes of β phase precipitation, aluminum 5083 h321 turned into evolved. Stabilizing annealing is achieved at the bloodless-deformed 5083 aluminum alloy sheet, in order that a part of Mg may be uniformly brought about within the alloy within the form of β phase, ensuring that the fabric after growing old softening nonetheless meets the overall performance requirements.

Within the production manner of 5083 h321 sheet, the amount of bloodless deformation after recrystallization annealing, and the temperature and time of stabilization annealing after cold deformation are 3 key method parameters that affect the very last residences of the 5083 aluminum plate.

At some point of the cold deformation method, as the amount of cold deformation increases, the plate lattice distortion and the degree of grain breakage will increase, and the large grains might be elongated along the rolling path to form a fiber or band-like shape, and a huge number of bits can be generated within the grains. The interaction between dislocations is improved, consequently, the strength of the alloy increases.

With the increase of the annealing temperature and the extension of the holding time of the stabilized annealing, the tensile electricity and the yield power will decrease. This is because of the massive deformation storage electricity amassed after the cold running of the plate, which reasons healing and softening all through annealing. Partial work hardening is removed, so the energy is reduced and the elongation is elevated.

As the quantity of deformation will increase, the intergranular corrosion resistance of 5083-H321 sheet decreases, and while the amount of deformation and the stabilization annealing time are the same, the intergranular corrosion resistance of the plate relies upon on the temperature of the stabilization annealing.A chilly deformation of 20% and a stabilized annealing system of a hundred and eighty℃/2h are the fine manufacturing methods for the three mm 5083 aluminum sheet.

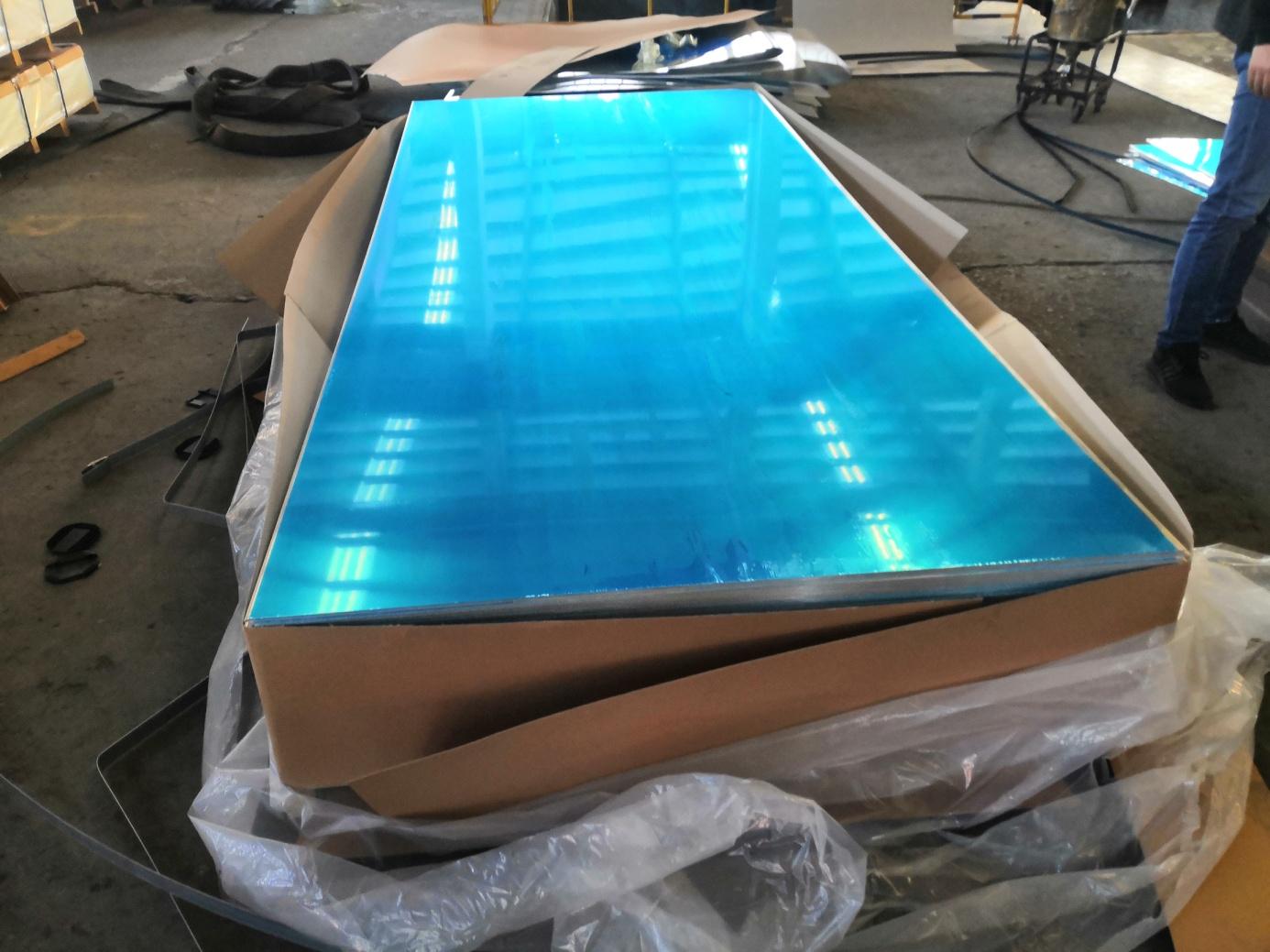

The manufacturing method of Aluminium 5083 H32

Read More

Gilmore Girls Revival - Netflix Eyes More Episodes

Netflix Eyes Continuation of Beloved 'Gilmore Girls' Saga

Following the immense success of the...

Duet Night Abyss – How to Add Friends & Unlock Co-Op

To enjoy cooperative gameplay in Duet Night Abyss, players need to connect with friends by adding...