The 1050 aluminum alloy is shaped from natural aluminum through added a small quantity of copper detail, and the 1050 aluminum plate has low power, superb formability, surface remedy assets, weldability and corrosion resistance. Except, the industrial pure aluminum has the traits of excessive plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but the power is low, it can't be reinforced by using warmness treatment, the machinability isn't suitable, and phone welding and gas welding are acceptable. The higher the purity, the decrease the hardness of the aluminum plate, within the one thousand series pure aluminum alloys, 1050 aluminum sheet plate has higher strength, it is nearly similar to 1060 aluminum.

As one of the unalloyed aluminum, 1050 aluminum sheet has low rate and excessive overall performance, so it additionally has wide applications. The thickness of 1050 aluminum plate sheet is zero.012-500mm. The tempers have soft state (O kingdom, H111), tough kingdom (H18, T6), medium hardness (H24, H22, H32, H112), etc. After other treatment or processing, the software scope of the 1050 aluminum alloy can be widen, which include 1050 mirror aluminum sheet, 1050color coated aluminum sheet, 1050 embossed aluminum sheet, 1050 aluminum trad plate, 1050 anodized aluminum sheet and 1050 brushed aluminum sheets. With so many overall performance advantages, 1050 aluminium can be carried out in day by day necessities, lighting fixtures device, reflectors, decorations, chemical enterprise bins, warmth sinks, signs, electronics, lamps, nameplates, electrical home equipment and other merchandise.

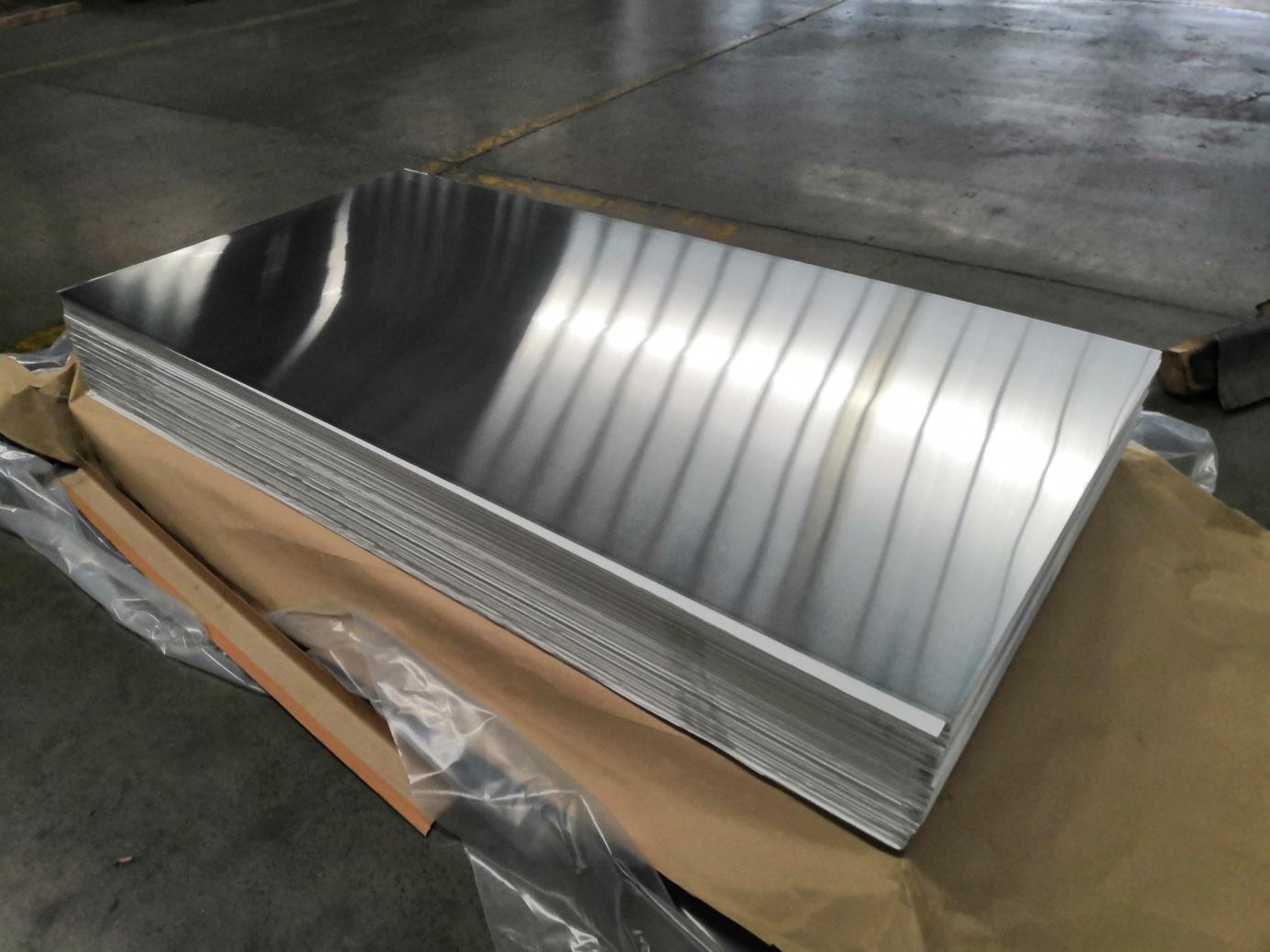

1050 aluminum plate sheet product

Read More

+>18+!%^%Xxx-Videos%!!<+ Austrian Xxx Videos agh

CLICK THIS L!NKK

Fortune Tiger Fast Spins: A Thrilling Slot Experience

Fortune Tiger is an exciting online slot game that has gained popularity among casino...

Natalie Roush Nude Boobs Wet T-shirt Onlyfans Set Leaked bna

CLICK THIS L!NKK