Aluminum sheets are a versatile and widely-used material in numerous industries due to their exceptional properties. Among the different thicknesses available, the .063 aluminum sheet stands out as a particularly popular choice for a wide array of applications. The “.063” measurement refers to the thickness of the sheet, which is approximately 1.6 millimeters. This thickness strikes a balance between strength, flexibility, and workability, making it ideal for both lightweight and sturdy applications.

In this introduction, we will explore the significance of .063 aluminum sheet, its characteristics, and its common uses, offering insights into why this particular thickness is preferred for many commercial and industrial projects.

What is .063 Aluminum Sheet?

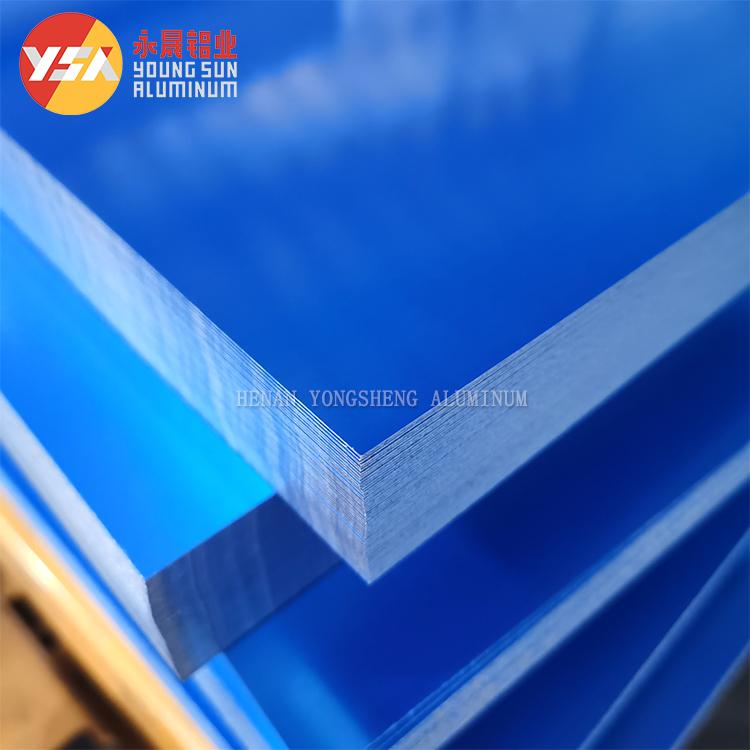

The .063 aluminum sheet is a flat, thin piece of aluminum with a thickness of 0.063 inches (or 1.6 mm), often used in various manufacturing, fabrication, and construction applications. The aluminum itself is known for its excellent strength-to-weight ratio, making it an ideal material for use where reducing weight is crucial while maintaining structural integrity.

Aluminum sheets come in various grades, and the specific alloy chosen for the sheet can greatly affect its properties, such as strength, corrosion resistance, and workability. Common alloys for .063 aluminum sheets include 3003, 5052, and 6061, each offering unique benefits depending on the application's demands.

Key Characteristics of .063 Aluminum Sheet

-

Lightweight: One of the most significant benefits of aluminum is its low density. A .063 aluminum sheet is much lighter than steel, which makes it easier to handle and transport without sacrificing strength.

-

Corrosion Resistance: Aluminum naturally forms a protective oxide layer on its surface, which makes it resistant to rust and corrosion. This feature is particularly beneficial for applications exposed to outdoor environments or marine environments.

-

Ductility and Malleability: Aluminum is highly malleable and can be shaped and formed without cracking. This makes .063 aluminum sheets easy to cut, bend, or weld.

-

Electrical and Thermal Conductivity: Aluminum excels in both electrical and thermal conductivity, making it useful in applications where heat dissipation or electrical conduction is required.

-

Aesthetic Appeal: Aluminum has a smooth, shiny surface that can be anodized or painted for aesthetic purposes, allowing it to be used in visible areas where appearance is important.

Common Applications of .063 Aluminum Sheet

Due to its blend of strength, weight, and durability, the .063 aluminum sheet is used in a variety of sectors. Some of its most common applications include:

-

Aerospace Industry: In aviation, where weight is a critical factor, aluminum sheets of various thicknesses, including .063, are used in the construction of aircraft components like panels, trim, and wing structures.

-

Automotive Industry: The lightweight nature of aluminum makes it ideal for use in car parts, especially for reducing overall vehicle weight. .063 aluminum sheets are often used in parts like body panels, doors, hoods, and other structural elements.

-

Signage and Display: The smooth, reflective surface of aluminum makes it a popular choice for signage, both indoor and outdoor. .063 sheets are often used for creating durable, weather-resistant signs and displays.

-

Electrical Enclosures: Given its electrical conductivity and resistance to corrosion, .063 aluminum sheet is commonly used to make enclosures for electrical equipment, protecting internal components from environmental factors.

-

Home Appliances: Aluminum sheets are frequently employed in the production of kitchen appliances, air conditioners, and other household products due to their combination of lightweight and durability.

-

Marine Applications: Aluminum's resistance to saltwater corrosion makes it an ideal material for marine environments. .063 aluminum sheets are often used in boat construction, marine parts, and other water-based applications.

-

Construction and Architectural Use: Aluminum sheets are also used in building facades, roofing materials, and interior decorations, particularly in projects that require a balance of light weight and durability.

-

HVAC Systems: Aluminum's thermal conductivity makes it perfect for heat exchange systems, including parts of air conditioning and heating systems. .063 sheets are used to create components such as ducts, fins, and coil covers.

Benefits of Choosing .063 Aluminum Sheet

-

Strength and Durability: Despite its lightweight nature, aluminum is highly durable and can withstand impact, abrasion, and general wear and tear.

-

Cost-Effectiveness: While aluminum sheets can be more expensive than other metals like steel, their durability, low maintenance requirements, and long lifespan make them a cost-effective choice in the long run.

-

Ease of Fabrication: The .063 aluminum sheet is easy to work with, offering superior machinability. It can be easily sheared, bent, or welded to fit specific project needs, making it a convenient choice for manufacturers and fabricators.

-

Environmentally Friendly: Aluminum is 100% recyclable, which makes .063 aluminum sheets an eco-friendly choice. Recycling aluminum requires only a fraction of the energy needed to produce new aluminum, making it a sustainable option.

Conclusion

The .063 aluminum sheet is a versatile, durable, and lightweight material with a wide range of applications across various industries. Its characteristics, including corrosion resistance, malleability, and ease of fabrication, make it a go-to material for projects that require both strength and lightweight properties. Whether in aerospace, automotive, marine, construction, or signage, this particular thickness provides the perfect balance of performance and practicality. For manufacturers, fabricators, and designers, .063 aluminum sheets offer a cost-effective, sustainable, and efficient solution to numerous design and engineering challenges.